-

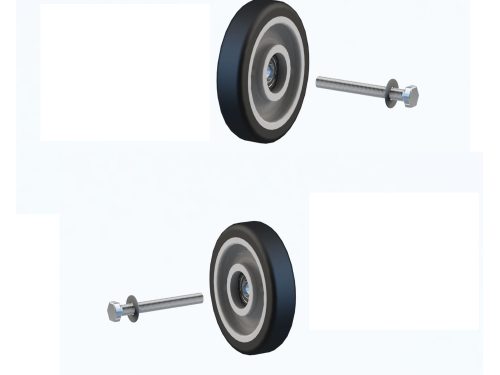

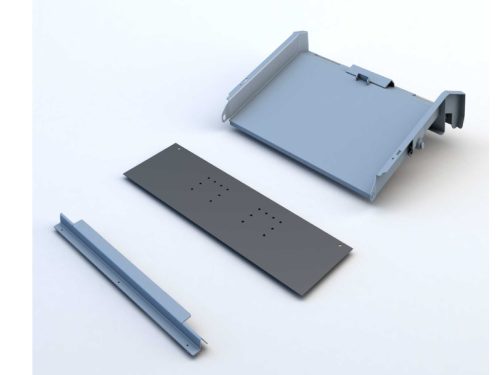

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.Application

Vehicle interface XL53 Vehicle interface XL46 in combination with pneumatic tire option -

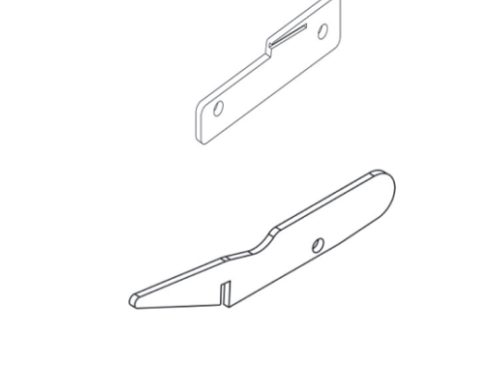

The Safety activator is part of the chassis. The Safety activator is the most important part of Dynnox. When loading an undercarriage in a vehicle, the unlocking of the legs is hereby ensured. But also the locking of the legs when unloading a chassis. This part is for the Dynnox L46. Note: the performance of the legs must be reset when these parts are replaced. See manual.

The Safety activator is part of the chassis. The Safety activator is the most important part of Dynnox. When loading an undercarriage in a vehicle, the unlocking of the legs is hereby ensured. But also the locking of the legs when unloading a chassis. This part is for the Dynnox L46. Note: the performance of the legs must be reset when these parts are replaced. See manual.Applications

Dynnox L46 -

The fixation locking knobs ensures that the frame is anchored in the brackets. Assembly requires some Dynnox expertise. You can find the instructions in the assembly film of the carrier.

The fixation locking knobs ensures that the frame is anchored in the brackets. Assembly requires some Dynnox expertise. You can find the instructions in the assembly film of the carrier.Applications

All models -

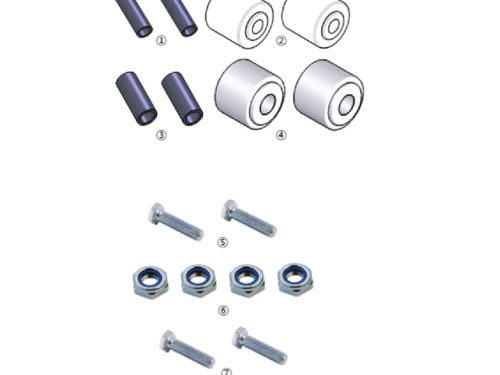

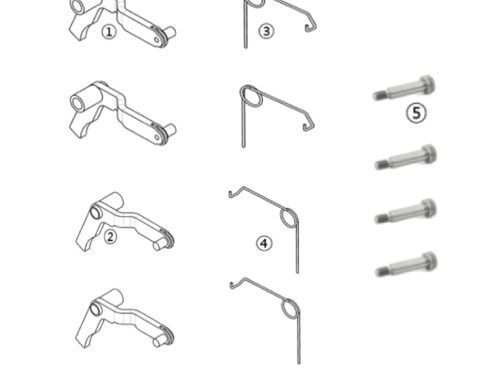

Set leg adjustment bolt + nut ensures that the legs move forward or backwards and therefore indirectly affect the play of the safety locks. You can understand their functions by watching the instruction film for carrier assembly.

Set leg adjustment bolt + nut ensures that the legs move forward or backwards and therefore indirectly affect the play of the safety locks. You can understand their functions by watching the instruction film for carrier assembly.Application

All models -

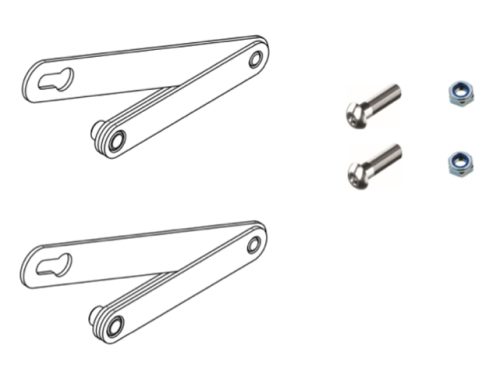

The levers loading platform secures the suspension of the loading tray when it is folded out. These can be easily disassembled so that the loading tray can be disconnected from the vehilcle interface. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.

The levers loading platform secures the suspension of the loading tray when it is folded out. These can be easily disassembled so that the loading tray can be disconnected from the vehilcle interface. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.Application:

Vehicle interface of all models -

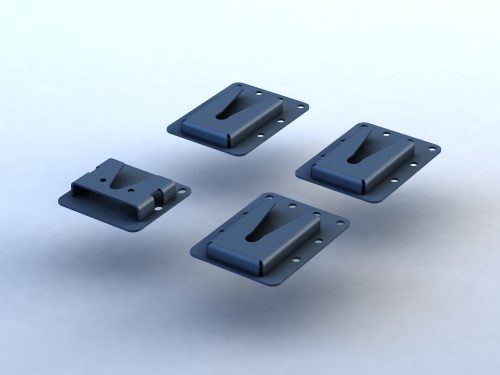

The Brackets are made of stainless steel and ensure the positioning and anchoring of the frame on the laoding tray. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.

The Brackets are made of stainless steel and ensure the positioning and anchoring of the frame on the laoding tray. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.Application

Vehicle interface of all models -

The safety locks are the part of the mechanism that lock and unlock the legs. Assembly requires some Dynnox expertise. The bolts should be mounted with loctite to prevent loosening of the screws. Note: when replacing these parts the clearance of the legs must be reset. See manual. Also watch our assembly video.

The safety locks are the part of the mechanism that lock and unlock the legs. Assembly requires some Dynnox expertise. The bolts should be mounted with loctite to prevent loosening of the screws. Note: when replacing these parts the clearance of the legs must be reset. See manual. Also watch our assembly video.Applications

All models -

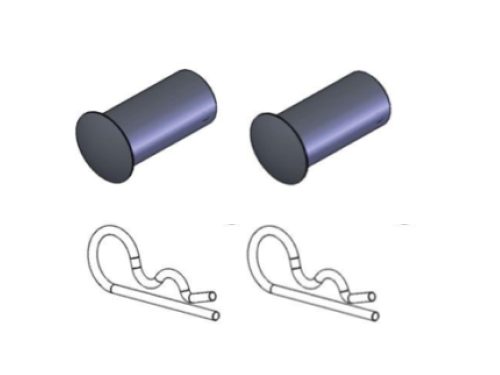

The “Shaft with spring cotter” forms the pivot points of the Loadingtray. These must be greased during assembly. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.

The “Shaft with spring cotter” forms the pivot points of the Loadingtray. These must be greased during assembly. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.Application:

Vehicle interface of all models -

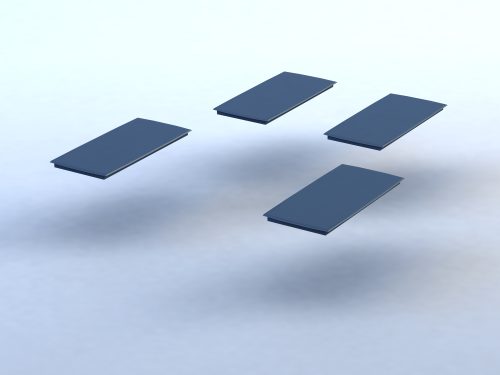

The Support plates ensure that the wooden plate is not dented by the wheels of the Carrier when it is loaded onto the veicle interface. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.

The Support plates ensure that the wooden plate is not dented by the wheels of the Carrier when it is loaded onto the veicle interface. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.Application:

Vehicle interface of all models -

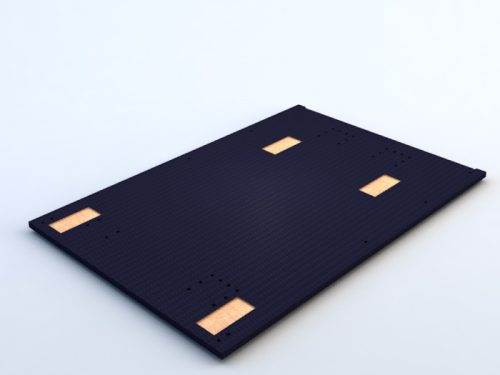

The positioning of all parts is pre-drilled and milled on both sides of the wooden plate. This makes mounting the parts of the vehicle interface on the car plate a kind of puzzle.

The positioning of all parts is pre-drilled and milled on both sides of the wooden plate. This makes mounting the parts of the vehicle interface on the car plate a kind of puzzle.Application

This plate is for the vehicle interface L46.Option

When the option of pneumatic tires is chosen, the wooden plate becomes 7 cm wider but not longer.Dimensions

864 x 1185 x 15 mmSafety

The positioning of the parts must be very accurate due to the positioning and locking of the chassis on the vehicle interface. -

The positioning of all parts is pre-drilled and milled on both sides of the wooden plate. This makes mounting the parts of the vehicle interface on the vehicle plate a kind of puzzle.

The positioning of all parts is pre-drilled and milled on both sides of the wooden plate. This makes mounting the parts of the vehicle interface on the vehicle plate a kind of puzzle.Application

This plate is for vehicle interface L46.Dimensions

794 x 1185 x 15mmSafety

The positioning of the parts must be totally accurate due to the positioning and locking of the chassis on the vehicle interface.