-

The chassis XL53 is the longest and widest Dynnox. The front and back are the same width. The car interface is not included. Due to its length and width, it is often used for bulky and / or complicated applications. An application of approx. 80 cm width, 140 length and 120 hight can be mounted on the frame, providing that the mass (load) is well distributed in the application. Read more about the XL53 or contact us!

The chassis XL53 is the longest and widest Dynnox. The front and back are the same width. The car interface is not included. Due to its length and width, it is often used for bulky and / or complicated applications. An application of approx. 80 cm width, 140 length and 120 hight can be mounted on the frame, providing that the mass (load) is well distributed in the application. Read more about the XL53 or contact us! -

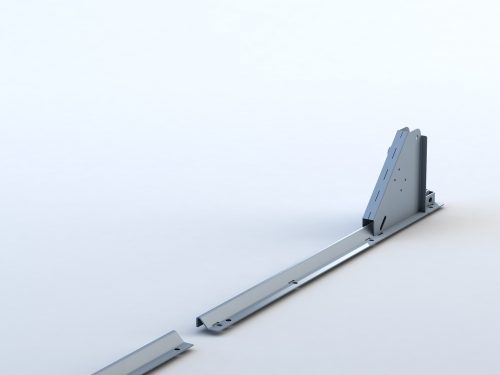

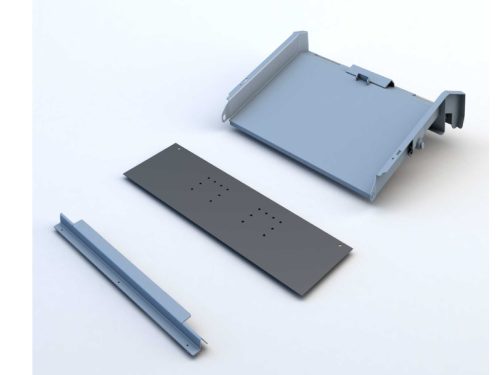

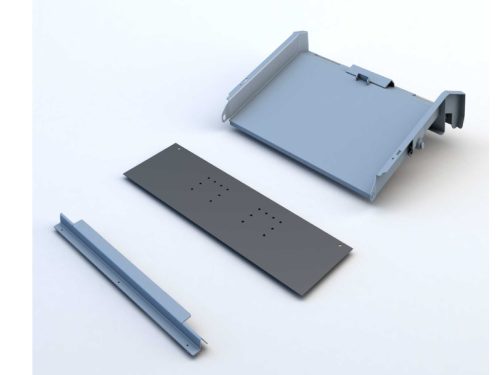

The guide rail left provides guidance for the carrier when it is being loaded. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.

The guide rail left provides guidance for the carrier when it is being loaded. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.Application:

Vehicle interface of all models -

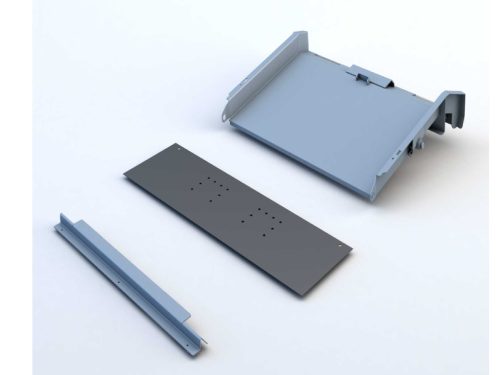

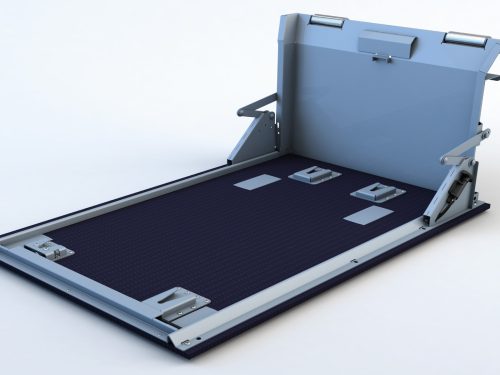

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.Application

Vehicle interface XL36 -

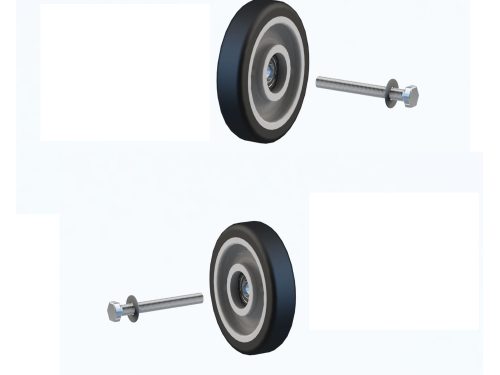

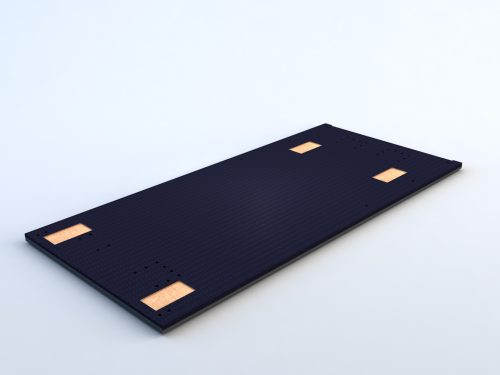

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.Application

Vehicle interface XL36 in combination with pneumatic tire option -

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.Application

Vehicle interface XL53 Vehicle interface XL46 in combination with pneumatic tire option -

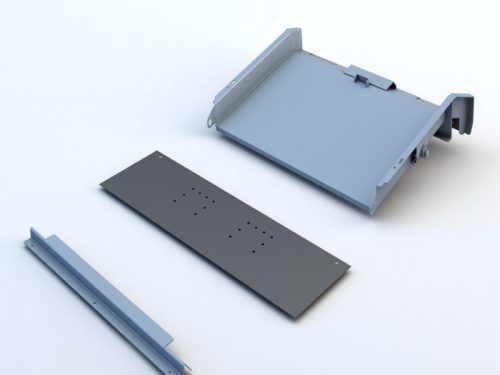

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.Application

Vehicle interface XL53 Vehicle interface XL46 in combination with pneumatic tire option -

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.

The loading tray is the platform on which the frame comes first. The sloping side of the platform ensures that the frame is lifted from the ground. The loading wheel should be halfway along the slope of the loading tray. At the front of the loading tray is also a small “platform” with a hook on it. This activates the mechanism and unlocks the legs. It is therefore important that the chassis is never higher than the loading tray.Application

Vehicle interface XL53 in combination with pneumatic tire option -

The Safety activator is part of the chassis. The Safety activator is the most important part of Dynnox. When loading an undercarriage in a vehicle, the unlocking of the legs is hereby ensured. But also the locking of the legs when unloading a chassis. This part is for the Dynnox XL36. Note: the performance of the legs must be reset when these parts are replaced. See manual.

The Safety activator is part of the chassis. The Safety activator is the most important part of Dynnox. When loading an undercarriage in a vehicle, the unlocking of the legs is hereby ensured. But also the locking of the legs when unloading a chassis. This part is for the Dynnox XL36. Note: the performance of the legs must be reset when these parts are replaced. See manual.Applications

Dynnox XL36 -

The Safety activator is part of the chassis. The Safety activator is the most important part of Dynnox. When loading an undercarriage in a vehicle, the unlocking of the legs is hereby ensured. But also the locking of the legs when unloading a chassis. This part is for the Dynnox L46. Note: the performance of the legs must be reset when these parts are replaced. See manual.

The Safety activator is part of the chassis. The Safety activator is the most important part of Dynnox. When loading an undercarriage in a vehicle, the unlocking of the legs is hereby ensured. But also the locking of the legs when unloading a chassis. This part is for the Dynnox L46. Note: the performance of the legs must be reset when these parts are replaced. See manual.Applications

Dynnox L46 -

The safety activator is part of the chassis. The safety activator is the most important part of Dynnox. When loading an undercarriage in a vehicle, the unlocking of the legs is hereby ensured. But also the locking of the legs when unloading a chassis. This part is for the Dynnox XL53. Note: the performance of the legs must be reset when these parts are replaced. See manual.

The safety activator is part of the chassis. The safety activator is the most important part of Dynnox. When loading an undercarriage in a vehicle, the unlocking of the legs is hereby ensured. But also the locking of the legs when unloading a chassis. This part is for the Dynnox XL53. Note: the performance of the legs must be reset when these parts are replaced. See manual.Applications

Dynnox XL53 -

The fixation locking knobs ensures that the frame is anchored in the brackets. Assembly requires some Dynnox expertise. You can find the instructions in the assembly film of the carrier.

The fixation locking knobs ensures that the frame is anchored in the brackets. Assembly requires some Dynnox expertise. You can find the instructions in the assembly film of the carrier.Applications

All models -

Set leg adjustment bolt + nut ensures that the legs move forward or backwards and therefore indirectly affect the play of the safety locks. You can understand their functions by watching the instruction film for carrier assembly.

Set leg adjustment bolt + nut ensures that the legs move forward or backwards and therefore indirectly affect the play of the safety locks. You can understand their functions by watching the instruction film for carrier assembly.Application

All models -

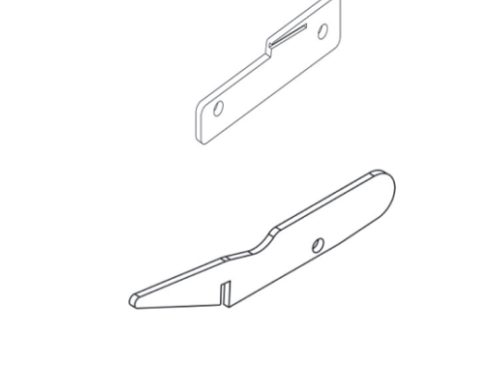

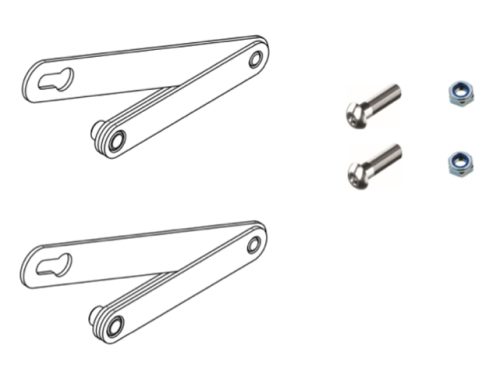

The levers loading platform secures the suspension of the loading tray when it is folded out. These can be easily disassembled so that the loading tray can be disconnected from the vehilcle interface. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.

The levers loading platform secures the suspension of the loading tray when it is folded out. These can be easily disassembled so that the loading tray can be disconnected from the vehilcle interface. For installation we advise you to watch the assembly film of the vehicle interface before starting assembly.Application:

Vehicle interface of all models